A top quality conveyor belt can not reach it's best performance without good service and support. SWR offers comprehensive conveyor belts services from belt design, installation, splicing, repairing and maintenance.

-

13

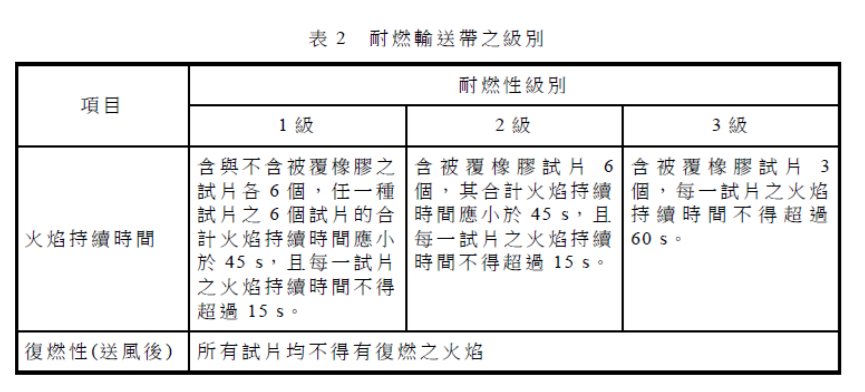

How to classify the flame resistance grade of conveyor belt?

According to JIS K6324/CNS10026, the flame resistance grades of conveyor belt can be divided into 1, 2 and 3. The requirements are as follows:

-

14

How to classify the heat resistance grade of conveyor belt?

According to ISO 4195 the heat resistance grade of conveyor belt, it can be divided into Grade 1: Heat resistance below 100℃, Grade 2: Heat resistance below 125℃, Grade 3: Heat resistance below 150℃. The requirements are as follows.

-

15

What is the allowable length of the matching limit for one set for drive belt?

According to ISO 4184 / CNS 745, when the belts are driven in sets, the allowable difference in length between sets is shown in Table 7 below:

-

16

What is the major failure of the drive belt?

- The drive belt slips on the pulley and cannot transmit power

- The 2 belt sides (working surfaces) of the drive belt are worn

- The drive belt is delaminated, torn and broken

-

17

The premise of the calculation formula of the transmission power of the transmission belt?

Is subject to the following conditions: when the friction coefficient is 0.25, the center angle of the winding is 120 degrees, and the allowable tension stress of the transmission belt is 0.18 mm2

-

18

What are the key requirements for drive belt design?

To ensure no slippage during operation, and to have a certain fatigue strength and service life.

-

19

How to distinguish the difference between NN and EP fabrics of the conveyor belt?

For the conveyor belt, the NN conveyor belt is relatively thinner. The yarn pattern of NN conveyor belt is relatively compact when viewed from the cross section; the yarn of the EP conveyor belt is relatively curved from the side, and the distance between the two peaks is relatively large. In addition, the NN conveyor belt is relatively soft, and the EP belt is hard.

-

20

How to deal with the uneven tension of the conveyor belt?

The deviation during empty running, if the deviation is weakened or normal after adding the conveying material, is caused by the looseness of the conveyor belt or the excessive initial tension. If the tension is too large, the conveyor belt jumps off the idler roller and floats and swings during operation. If the tension is too small, the friction between the roller and the conveyor belt will decrease, the power of the conveyor belt to advance longitudinally will decrease, and the resistance of lateral movement will decrease, resulting in deviation. Appropriate additions and reductions can be taken to solve the problem. The tensioning stroke can be adjusted for the belt conveyor with screw tension or hydraulic tension.

-

21

Design requirements for drive pulleys?

When designing the pulley of the transmission belt, the structure should be convenient to manufacture, the weight distribution should be uniform, light and excessive internal stress due to casting should be avoid. In addition, the working surface of the wheel groove should be smooth to reduce the abrasion of the drive belt. According to ISO 4183, the working surface roughness of the drive wheel groove for industrial use is 3.2 μm, and for high-performance transmission, it should reach 1.6 μm.

-

22

The tension force required when the power transmission belt being installed in the drive belt?

-

23

Storage suggestions for conveyor belts?

The conveyor belt should be stored according to the following methods.

- Keep dry and cool - 10 °C to 25 °C, about 65% humidity, with good ventilation.

- Avoid direct sunlight.

- Avoid storing with acids, lubricants and solvents at the same time, the vapor may damage the cover rubber of the conveyor belt.

- The conveyor belt cannot be placed directly on the ground, and must not be placed on the edge that may cause inclination.

-

24

What is the pros and cons of power transmission belts?

Pros:

- The structure is relatively simple, and its manufacturing process and installation accuracy requirements are lower.

- Simple to use and convenient to maintain,can be used in occasions where the center distance between two axes is relatively large.

- It can run smoothly and the noise generated during operation is very low. Drive belt has good elasticity and can play the role of buffering and absorbing vibration.

- When overloading occurs, the transmission belt will slip on the pulley.

Cons:

- The outer dimension is relatively large, and the efficiency of its running is relatively low.

- During the performance, the accurancy of the transmission ratio cannot be sure.