| Profile | AV10/10A/9.5 | AV13/13A/13 | AV17/15A/17 |

|---|---|---|---|

| Belt Width (mm)≈ | 10 | 13 | 17 |

| Belt Height (mm)≈ | 8 | 9 | 11 |

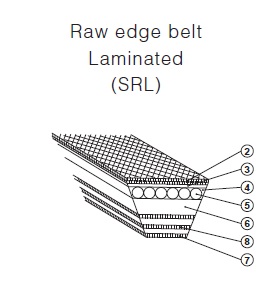

| No | Name | No | Name |

|---|---|---|---|

| 1 | Wrapping fabric | 5 | Tensile members |

| 2 | Top fabric | 6 | Compression rubber |

| 3 | Top cushion rubber | 7 | Bottom fabric |

| 4 | Adhesion rubber | 8 | Laminate fabric |

| Feature | SWF | SRL | SRC |

|---|---|---|---|

| Resistant to side pressure | ○ | ✩ | ✩ |

| Resistant to heat | ○ | ○ | ✩ |

| Resistant to flexibility | ○ | ○ | ✩ |

| Resistant to dust | ○ | ✩ | ✩ |

| Elongation | ○ | ✩ | ✩ |

| Noise | ✩ | ✩ | ○ |

○: Good

✩: Excellent

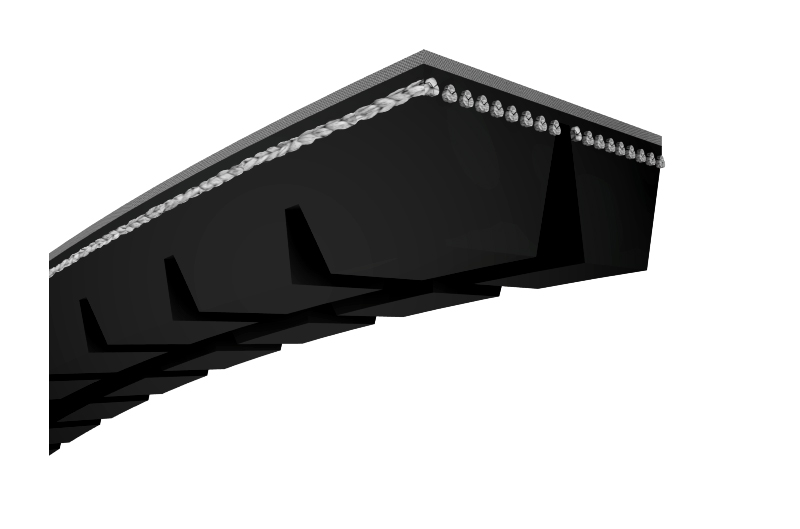

The differences between raw edge cogged and laminated is the presence of the cogged at the base rubber.

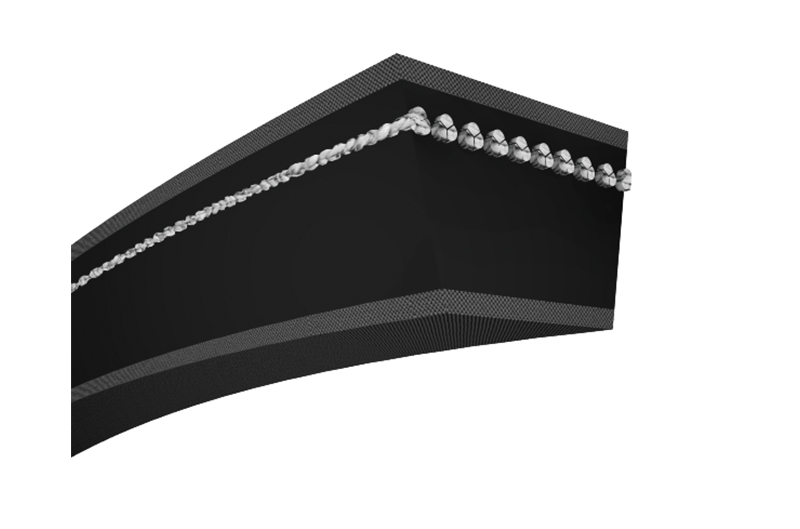

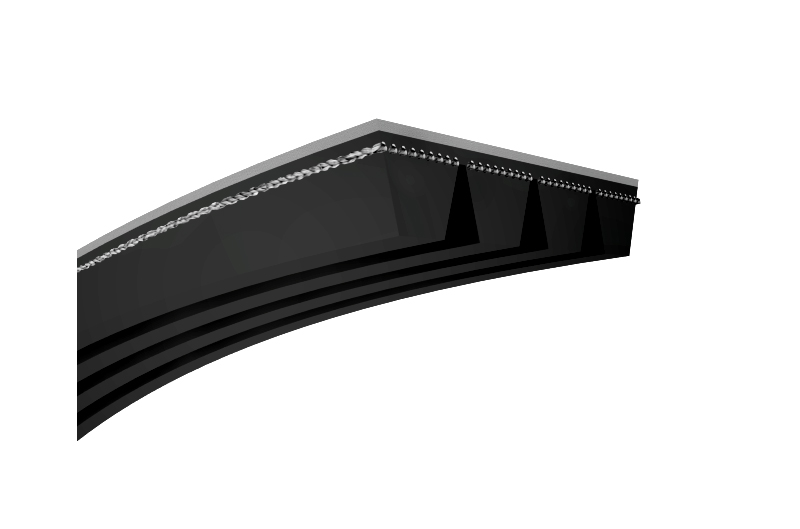

Raw edge laminated belts are produce to fulfill the needs when you need the drive to bring tough and high power rating applications. San Wu designed this belts with a covered with multiple fabrics in the bottom to reduce noise, which act similar result to wrapped belts. Compared to wrapped belts, Laminated Belts performance better with resistant to side pressure, dust and elongation.

- High flexibility

- Excellent in resistant side pressure and dust

- Efficient in reduce noise

- Features Oil & Heat Resistance

- Low maintenance requirement

- In accordance with ISO 1813 Antistatic Requirement

- Meets JSO E107 and ISO 2790 Standards

- Temperature resistances with -30 ~ 110 °C